An extract from Saab´s staff news magazine VIPS (Vi på Saab) No.5 1964.

Adapted and compiled by Ray Beaufoy – January 2024.-

Trollhättan

During the past year, the test and development department at Saab-T has been preparing to move into new offices and workshop space. Their current location has been extended by 240 m2 which, when completed, will provide much needed space for new engine test rooms and rig-test laboratories. New stores, offices, and conference rooms etc are also being added.

A further 1400 m2 area has also been added for rig testing of body in white and chassis components etc.

In total the test facilities working area has been increased by 20 % and will serve to provide a more effective and concentrated working area for future car development at Saab.

CAR DEVELOPMENT UNDER ONE ROOF

Saabs test laboratory now established in new premises.

Laboratories

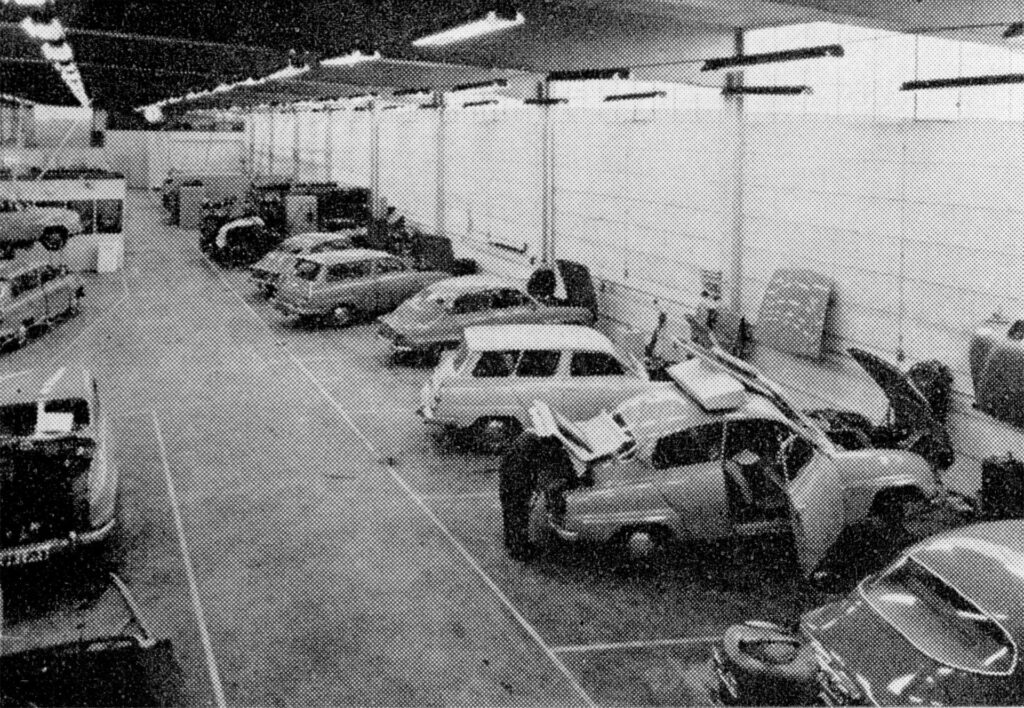

The vehicle test laboratory includes both the Chassis and Car body laboratories. This part of the building is 20 X 70 m in size and connects with a special test area where three noise suppressed test cells are located.

The building also includes a car wash and water test area and a further room for specialised development tests.

Endurance testing

In one of the test rooms gearboxes are tested for durability along with measurement of gear train noise levels.

In an adjacent test room, endurance testing of chassis related components takes place -here component that are subjected to dynamic forces i.e. wheel hubs etc. are checked for strength and reliability. This rig also provides the possibility of testing drive shafts, CV joints and lubrication qualities etc. The lubrication grease used on 1964 model Saabs is the product of testing on this rig.

In a similar way Saabs seat frames are tested for reliability – one particular test to a seat frame was noted to have been terminated after a defect was observed after 75000 Forward / Rear movements under high load had been applied to it – here the test result proved that Saabs durability target for the seat frame had been fulfilled and the frame was expected to withstand normal use by the driver and passengers.

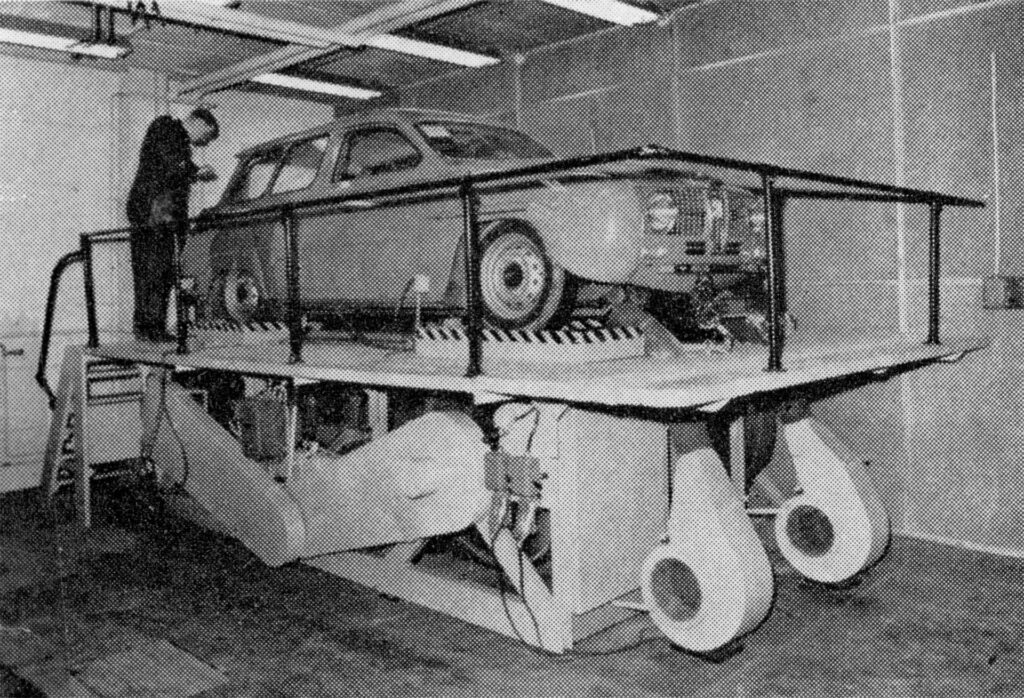

The third test room holds a special rig for dynamic vibration testing of a complete vehicle. Here a complete car can be driven onto a special rig which includes a set of rotating rollers at each wheel modified with several radial blocks (up to 100 mm in height) which during rotation of the roller brings about a bump and rebound condition of the wheel rolling over them. This can be done at differing road speeds. Test cycles ranging from 25 to 100 hours duration are performed and follow pre -determined driving characteristics. Most often these tests are performed with the vehicle fully laden. Extensive braking and acceleration tests can also be made here.

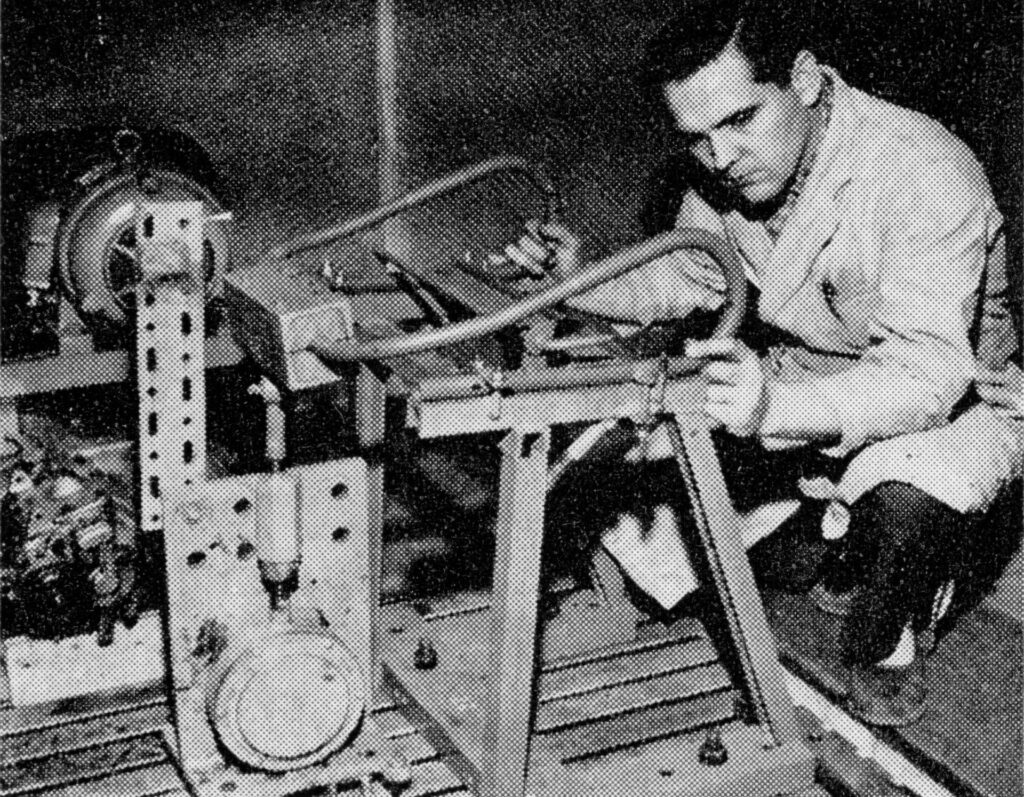

Versatile test rigs

Many of the test rigs are constructed using Meccano type steel framework / beams etc. which are very versatile and easily adapted to different test requirements – i.e. endurance test of windscreen wiper assemblies, heater motors, lights, and switches etc.

In a special test room gearbox noise levels are measured together with a special rig for evaluating ease of fitment and removal of gearboxes during service.

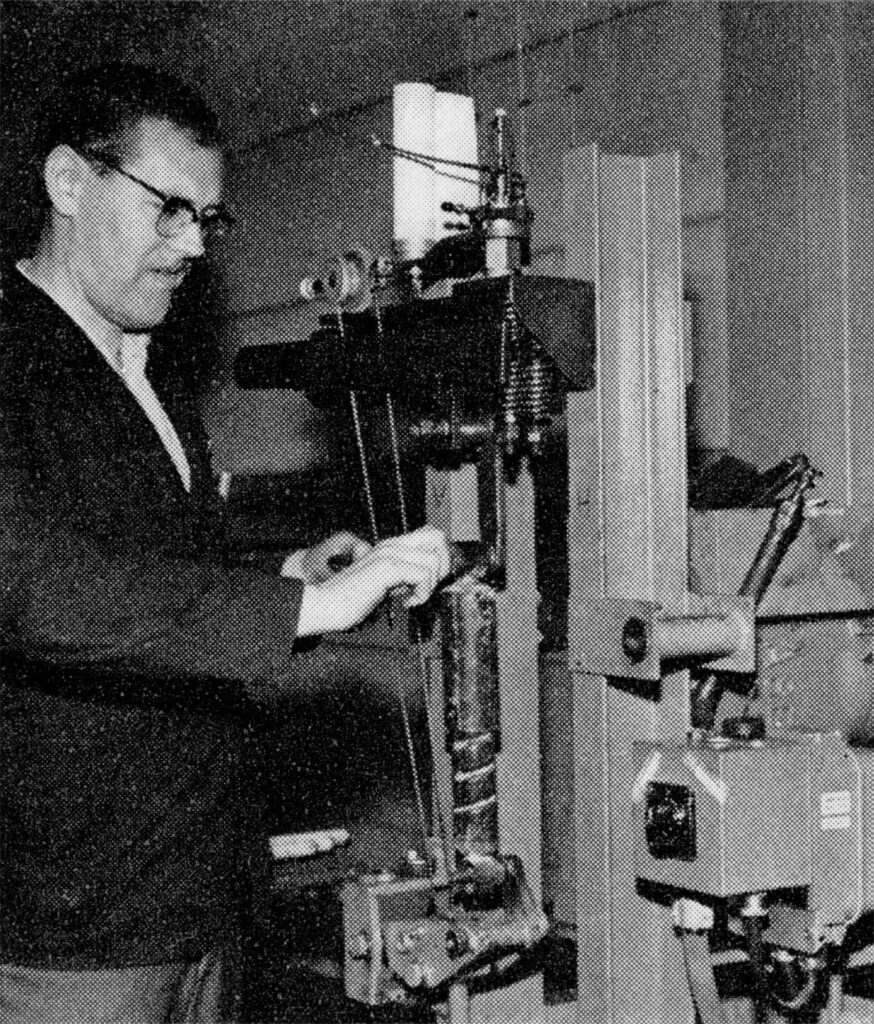

A further specific area is set out for advanced checking of wheel geometry – far more sophisticated than which is used in today’s service workshops – having also the advantage of being able to be used by the vehicle certification agencies during type approval etc.

Quality control of vehicles selected at random from the production line are also checked in the large test hall.

Experimental stores and engine test rooms.

Between the large car hall and the old engine laboratory (the main area) now holds the stores and the engine test-rooms. The stores now include the main central stores supplying both the engine and the complete vehicle test departments.

The area for the engine tests has been completed in two phases -In November ,6 new engine test dynamometers are to be installed and fully operational. A further area of comparable size has been reserved for completion later in the year. Six new dynamometers ,needed for more extensive endurance testing ,will serve as a most welcomed addition to the current dynamometers.

Seventy thousand litres test fuel

The increased engine test testing has demanded a larger supply of test fuel – to cover this, new fuel tanks have been installed – two tanks holding 25000 Litres each and a further tank holding 10000 litres – earlier a single tank holding only 10000 litres (sufficient for all test work) also remains.

The new test and development area has also needed to be equipped with its own drive-on scales where vehicle axel weights can be established -necessary in certification and type approval and for checking continuity of production vehicles. Such measurements were previously made at a private company outside of Saab.

New offices for development staff.

The new engine and test laboratory now stands close to Saabs own proving ground where vehicles are evaluated upon different road surfaces, road inclinations and even whilst driving through a special water trough – re earlier VIPS articles in homepage.

This new building has been a vital addition to the development of Saab vehicles for the future where rational and effective testing is necessary to be done in order to ensure Saabs high quality targets are fulfilled throughout many rigorous and diverse driving conditions.