December 2018 – Priming

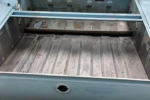

The project has made progress despite some very laborious work needing to be done removing old paint and sealing material from interior panels, engine compartment and around the trunk area. After many hours of hard work however the body shell was finally ready for a coat of primer to be applied.

Spraying inside in an enclosed area i.e. garage, incurs that fine paint mist seemingly gets sprayed everywhere! As a precaution Åke and his brother Leif decided to wait for some fine weather and then spray if possible, outside of the garage area. A large plastic cover was therefore spread out over the entrance to the garage to provide protection from any paint overspill etc. With all initial preparation carefully done the body shell was placed at the garage doors ready to be moved outside. Unfortunately, on that exact day the thermometer showed -2 °C, with an occasional fall of snow! Between snowfalls however the body was rolled out of the garage and the underfloor sections were sprayed with primer. The car body shell was then returned to the garage. Once reaching the correct temperature, the interior body sections, wheel arches, engine compartment and the new side panel were also primed.

In mid-November Åke and I travelled to Linköping to meet up with Bo Lindman who had two lightweight rear fenders and a fibre-glass trunk-lid for our project car. These components, used on a previous ice racing car, were somewhat blemished and had several holes that needed to be attended to.

The next step was to spray the cars underside with the surface paint supplied by Lackman. A litre of Saabs competition department classic Saab R2, Toreador Red, had been prepared by the company and after a week or so the underbody was finally sprayed.

After hardening the body was re-fitted with its underbody support fixtures and pivoting wheels allowing then rotational support cradle to be removed and the car being lowered on its support wheels to the garage floor.

It was now possible to concentrate on renovating some of the bodywork’s integral components such as i.e. the door-hinges, vents, hood support fixtures etc. Towards making the car as light as possible, all unnecessary metal together with the window adjustment mechanism were removed from each of the door assemblies. On the Group 3 competition cars the door window itself was adjusted and held in place by a single leather strap – our G3 project car is also planned to be of the same design.

For several years the original blue car had been used in numerous car competitions – this was particularly evident from the numerous blemishes etc that the car’s exterior panels had received. The damage has now been repaired together with the filling of several small holes also being found. Following sanding down and cleaning, a coat of primer was also needed.

We have now received the GT driver’s seat from Anita Lindholm at the Håby sewing company. Anita had done a brilliant job of bringing the seat up to its original condition.

Prior to the final spray work being done, some more time was taken smoothing down all visible body surfaces until a matt finish worthy of being sprayed over with a top coat had been achieved. This took also several hours to complete but was worthwhile and produced a very satisfactory result.

The final phase of all the work originally planned to be done in Åke´s garage in Munkedal, i.e. fitment of the hood, doors and body wings, etc. has now been completed and the car is now ready for NEVS to start work on applying the final coats of paint. NEVS have indicated that they required the car to be delivered with doors and the hood in place. Fender panels and the trunk lid should be delivered to them separately as they will all be sprayed on both on the inner and outer surfaces.

Once a suitable covered transporter has been found the car will be delivered to NEVS for the final application of surface paint. Once this is completed the car will then stand over the Christmas holiday break until January where re-assembly of the complete car will begin.