Historical Saab

Translation compiled and adapted by Ray Beaufoy August 2024 from Saabs staff magazine VIPS 1: 1965.

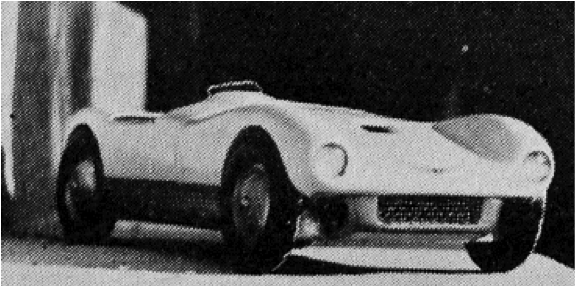

A huge sensation was created this year at the Stockholm Motor Show when Saab revealed a new 2-seater Sonett1, sports car.

Taking everybody by surprise the sleek little sports car was praised highly by the motoring press -the `Motor´ car magazine described it as “the icing on the top of the cake”!

Apart from the cars design and technical specifications – what was so remarkable was that the sports car was built in total secrecy – only a very small number of Saabs engineering staff knew about the sports car project – development of the car was performed under the highest degree of secrecy right up until it being presented on the 16 March 1956 at the Stockholm motor-show.

All work on the vehicle had been completed in a small, secluded workshop on the outskirts of Trollhättan. Rolf Mellde, the cars designer, and chief development engineer informed VIPS how the car initially came about and the early development and assembly of the sports car.

During the spring and summer of 1954, the idea of Saab building a sports car began to be taken very seriously, some initial sketches were drawn up, and a scale model was made of both car’s under-carriage (the “box” as it was known) and of the cars body shell itself.

At an early stage some of Saab’s aircraft designers and engineers were consulted and to assist in making engineering calculations regarding the car’s structural strength and ride and handling characteristics.

To obtain the lowest possible body weight in combination with the highest possible structural strength a lightweight box section bodywork construction, like the methods used in aircraft fuselage design was decided upon.

Enthusiasm for the project soon took off and from the simple early sketches a sports car soon began to take shape. Once the key features of the project had been established the project needed to be approved by Saab’s management.

Some of the main points presented to Saabs management in support of the Project …

a. Saab engineers were eager to build a sports car and to gain knowledge regarding sports car performance and mechanical requirements i.e. engine, transmission, steering, brakes, tyres etc

b. The Saab 93 engine could be used -modified to extract a higher Power rating.

c. To gain first-hand experience in building a body shell using a fiberglass laminate.

d. Many engineers at Saab felt that a sports car could give Saab increased publicity as a car manufacturer.

Approval for the project was finally given by Saabs management and secret design and development work was started in a small, secluded workshop close to the factory.

Early in the project Saabs aircraft engineer Erik Nilestam was contacted to gain his expert viewpoints of the project and soon thereafter a team of Saabs leading engineers i.e. Lars-Olov Olsson, Olle Lindqvist and Gösta Svensson became involved.

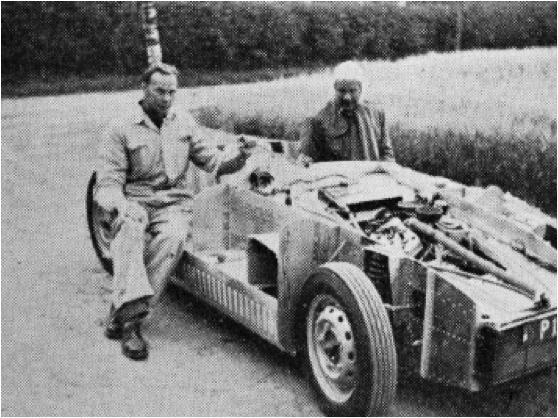

Work on the undercarriage started in January 1955. A former aircraft technician was engaged to perform this work as the box itself was to be made of riveted light metal panels -similar to the construction of aircraft fuselage. After a few months, a 1:1 scale plaster and wood model was complete and used as the pattern for moulding the plastic bodywork shell.

The Saab car’s designer, Sixten Sason, who had been involved in these discussions from the beginning and became heavily involved in sketching the final lines of the bodywork ….

After the plaster model began to take shape contact was made with engineer Norrby at SOAB in Gothenburg, renowned for their expertise in plastic/ fibreglass panel manufacture. Production of the plastic body shell then continued throughout the summer with Gösta Svensson taking a leading role in development. At the same time Lars-Olov Olsson participated in chassis development issues whilst Olle Lindqvist was heavily involved in tuning the Saab 93 engine.

Just before midsummer 1955, the chassis was complete, and the engine and gearbox were finally mounted in place and the car stood on its own wheels for the first time waiting for completion of the body shell.

Following late assembly work and final adjustments, the first test drive was made with (the box) at 3 a.m. on a foggy September morning. The limited testing time proved that the car possessed the driveability and performance characteristics that the engineers were aiming at.

At the same time as final tuning of the chassis and engine was taking place the fibreglass body shell began to take shape. On October 14, the at 2 am the car was finally complete. At dawn, the company management were given the good news.

Technical Information

The Sonett uses drive-line components from the Saab-93 and the 93-engine tuned to approx. 57.5 hp at 5,000 rpm. Maximum torque rating had been calculated to peak at 88 Nm at 3500 rpm.

The cars bodywork i.e. the bonnet, doors, and rear boot, are all made of fiberglass laminate.

The box construction for attaching the chassis details is completely made of riveted light metal. – this design is the same as that used in modern aircraft construction to create an exceptionally low weight of this unit (71 kg).

Press intervention – a flashlight helped keep the secret! `

Saab assigned advertising photographer Folke Sörvik from Göteborgs-Tidningen, in Gothenburg to take photos of the vehicle in time for the motor show in Stockholm. All pictures were to be taken at night.

Folke informed that on one occasion, the Sonnet had been prepared ready to be photographed together with a Saab 93 and needed to be rolled out of the workshop to a close by open road.

When everything was ready for shooting, the owner of a close by house suddenly emerged from the darkness and wondered what was going on? Saab technicians quickly pointed their flashlights at him so that he was blinded by the strong lights restricting his view of the scene!

He settled for some quickly given excuse and left the scene without any further questions or suspicion.

Professional photos

It was important to take several safety measures when filming indoors. The workshop where the car was so small that pictures of the entire car had to be taken from outside the workshop looking in. Pictures from above, where the car’s lines could be fully appreciated were taken from the photographer standing on a ladder positioned on a newly erected wooden platform.

Special photocell-controlled electron flashes were used for the official photos of the vehicle – and since most of the pictures were taken without people being present, it was possible to make a series of repeated flashes for each picture.

Photographer Folke Sörvik took over1200 photos related to Saab, more than half of which were of the Sonnet.

Every night during photograph sessions waste baskets had to be thoroughly checked so that no photos relating to the Sonett were left there. The secret had to be kept!

Nightly testing -noise complaints

Even the tests checking chassis performance were conducted at night on quiet roads close to the garage. A schoolteacher living close to the section of the road where the tests took place was notably disturbed by the high noise levels of a certain sports car that roared past his home every ten minutes. His complaint was taken seriously but did not stop further testing to any great degree.

| Data: | |

| Weight: | ca 500 kg |

| Track F/R: | 1220 mm |

| Wheelbase: | 2210 mm |

| Total length: | 3485 mm |

| Total width | 1420 mm |

| Height: | 825 mm |

| Engine | |

| Cylinder volume: | 748 cm3 |

| Power (max): | 57,5 hk at 5000 rpm |

| Torque (max): | 65 kpm at 3500 rpm |

| Compression ratio; | 10:01 |

| Gasoline: | 85 octane |

| Performance (preliminary) | |

| Acceleration 0-80 km/h | 8 sec |

| Acceleration 0-100 km/h | 12 sec |

| Standing start ¼ Eng. Mile | 18 sec |

| Standing start 1 km | 24 sec |

| Standing start 1 Eng.mile. | 48 sec |

| Max speed (open / closed) | 160 / 200 km/h |